Specifications

| Style | Rosin Press - AIR or Rosin Press AIR + Air Compressor |

| Color | Black or Red or Blue or Gold or Aluminum (Polish) |

| Power | 110v/120v 1P 60hz |

| Input | 15A Output 3.5 |

| XL Heat Plate | Rectangle 9" x 5.4" |

| Cylinder | 12-35 Ton |

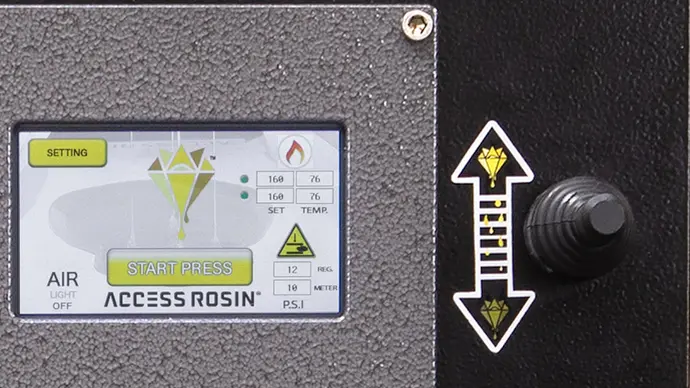

| PID | Dual Plate Controllers |

| Thermocouple | K-Type |

| Switch | On/Off |

| Legs | 6" |

| Size | 12" (l) x 16" (w) x 32" (h) |

| Weight | 75lbs |

Suggested Alternatives:

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.

Spin Flow Vibrator

Spin Flow Vibrator

FLUID - Traditional Hand-Pump

FLUID - Traditional Hand-Pump AIR - Automatic & Manual

AIR - Automatic & Manual The Kwäd - Automated / Muti-Pouch

The Kwäd - Automated / Muti-Pouch

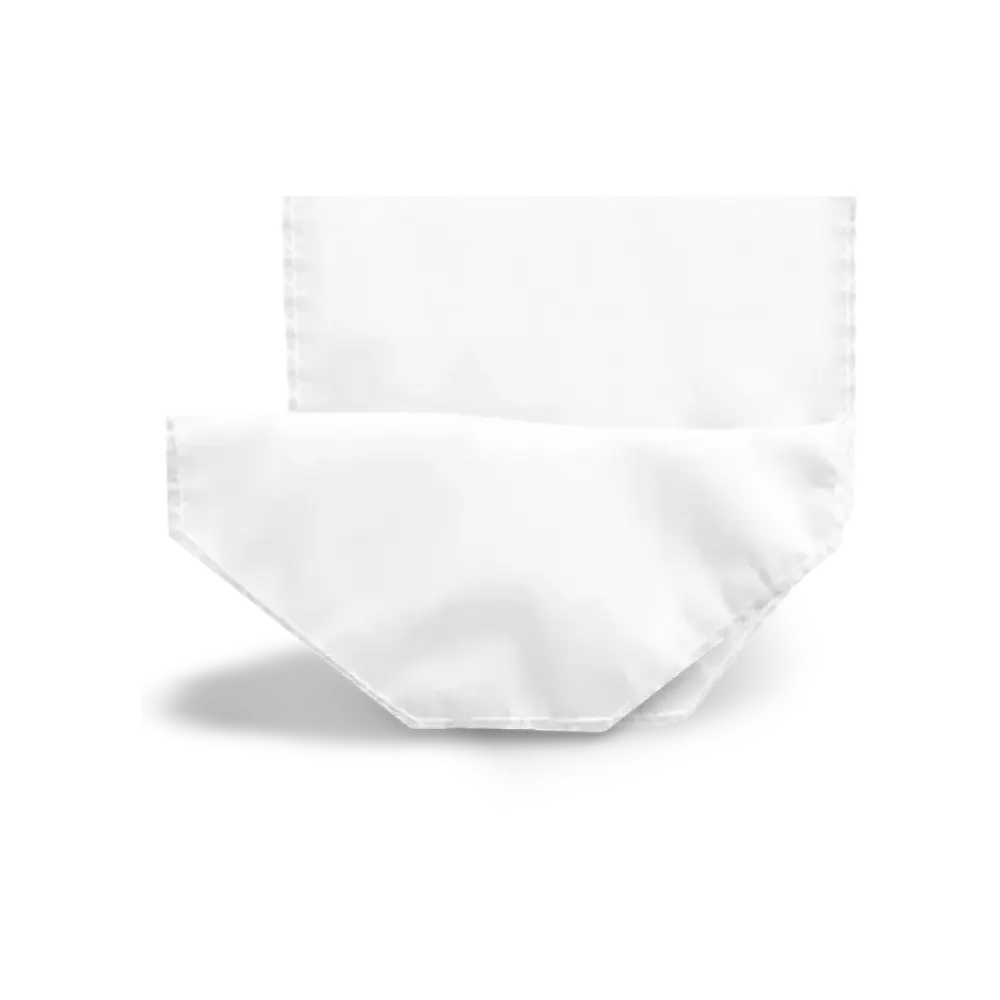

Wash / Sieve (Bubble) Bags

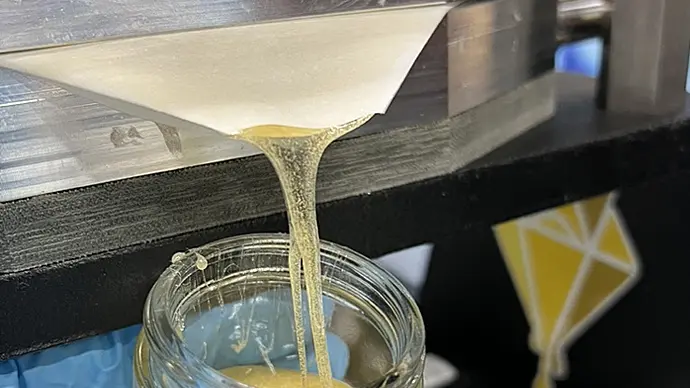

Wash / Sieve (Bubble) Bags Rosin Bags

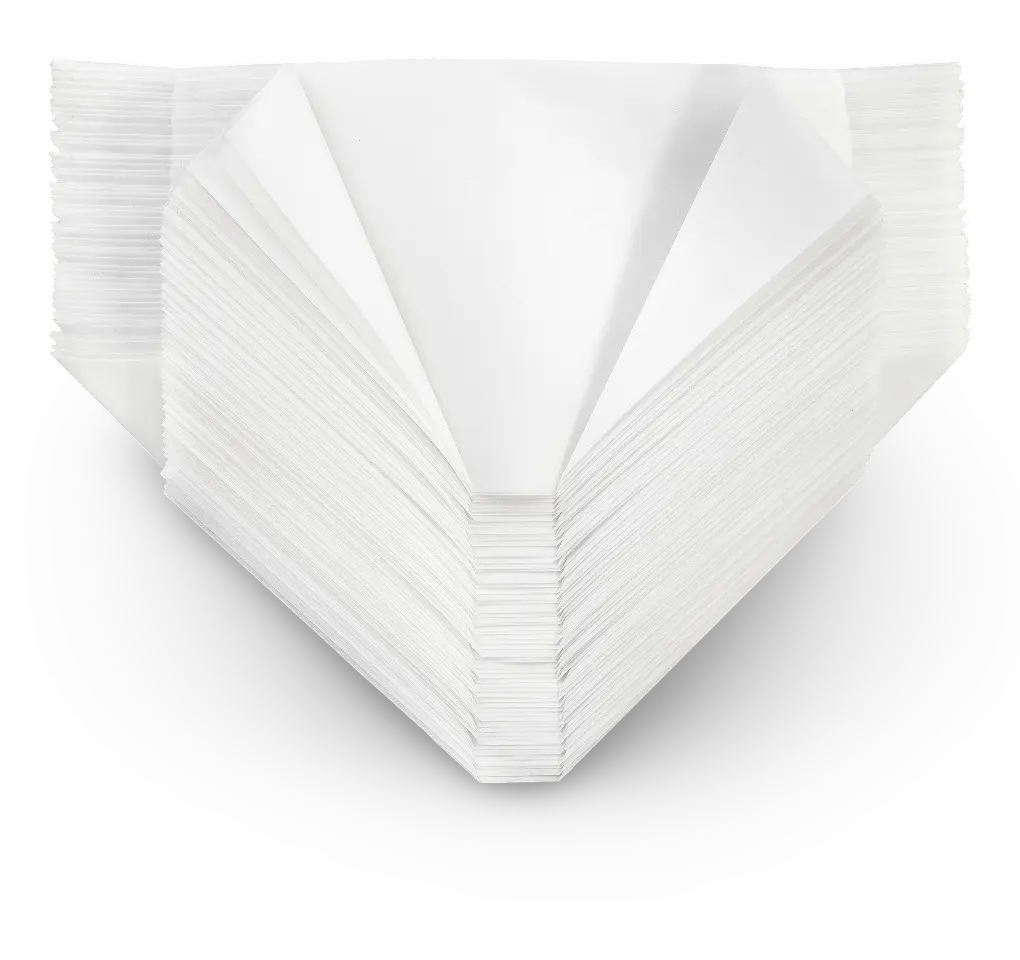

Rosin Bags Parchment Paper

Parchment Paper

Harvest Right

Harvest Right Holland Green Science

Holland Green Science Accessories

Accessories